A New Take on the I-Beam: Lumber Core + Metal Plate Flanges

When we think of engineered beams, products like LVLs, glulams, or manufactured I-joists usually come to mind. They’re strong, but they all require factory presses, adhesives, or specialized production. What if there was a way to make an I-beam in the field, using nothing more than dimensional lumber and stamped metal plates?

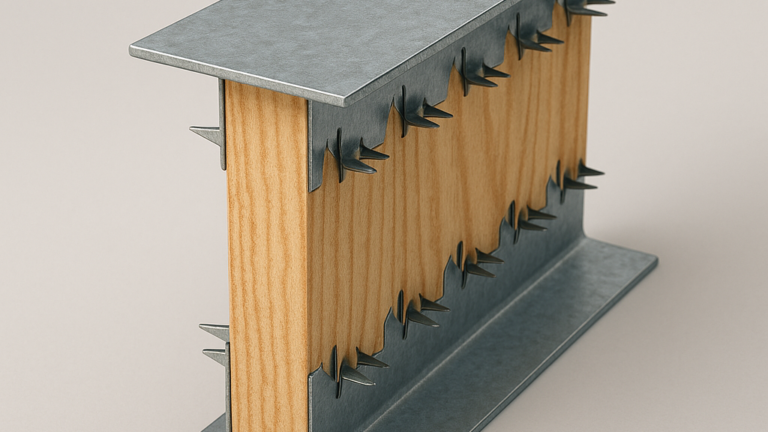

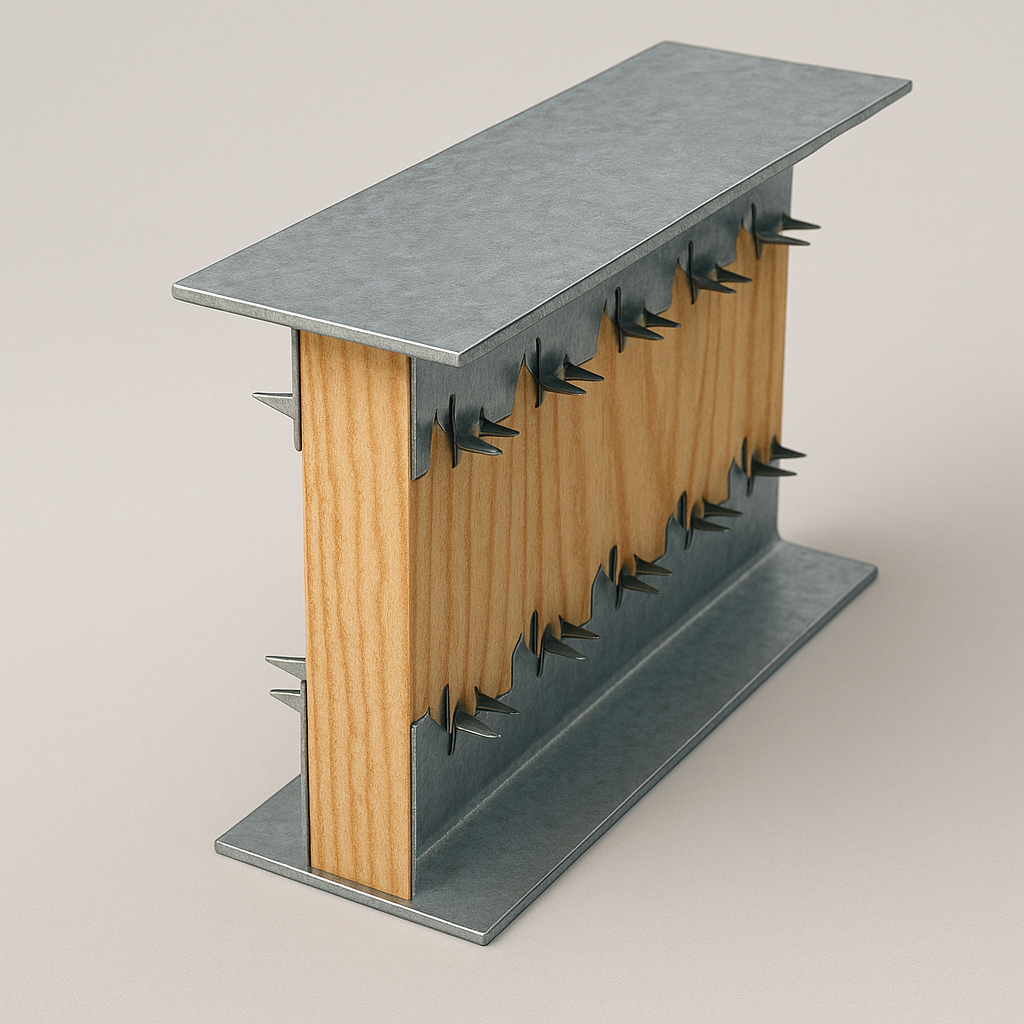

That’s the idea behind this concept: metal plates that transform a 2×4 into the web of an I-beam.

How It Works

- Core (Web): Start with a standard 2×4 or 2×6.

- Plates (Flanges): Two long strips of steel (around 8 ft × 4 in).

- Punch-Out Flaps: Stamped from the plates, these flaps bend inward to cradle the 2×4. They keep the lumber aligned and provide a place to drive screws.

- Push-Out Nails: Like the teeth on a truss plate, these hammered-in connectors bite into the wood, giving immediate grip and shear transfer.

Once both plates are installed, the 2×4 becomes the web and the plates become the flanges — creating a hybrid wood-steel I-beam.

Why This Matters

- Field-Assembly Friendly: No glue presses or factory lines needed — you can assemble with hand tools.

- Stronger Than Dimensional Lumber Alone: Steel flanges take the bending loads, while the wood resists shear.

- Modular: Works with different lumber sizes. A single product line could adapt to 2×4, 2×6, or laminated stacks.

- Redundancy: Teeth provide instant hold, while screws through the flaps lock the plates long-term.

Applications

- Roof beams and rafters

- Floor joists in remodels

- Temporary or modular construction where portability matters

- DIY projects where engineered lumber isn’t available

The Vision

Imagine walking into a hardware store and picking up “I-Plate Kits.” Toss in some 2×4s, and you can assemble hybrid I-beams right on site. Stronger than wood, lighter than steel, easier than LVL.

This idea takes inspiration from the Simpson Strong-Tie truss plates, but reimagines them for bending members rather than truss joints. With modern stamping presses, this could be a scalable and cost-effective way to make beams anywhere lumber is sold.